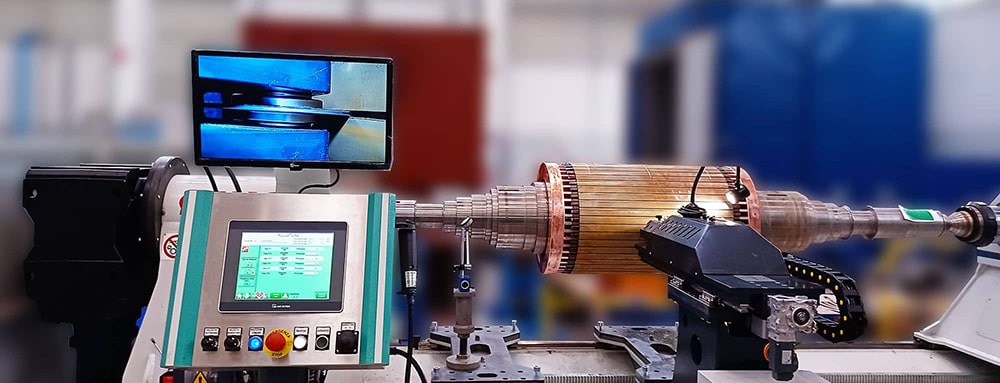

SWAGING MACHINES

Machines designed to perform the automatic swaging of rotor bars, which involves locking them inside the rotor slot through mechanical deformation, using a pressing action.

- Acceleration of swaging operations.

- Control of the locking process.

- Safety and repeatability.

- Fully automatic work cycle with rotor indexing via laser and automatic search for the midpoint of the first bar.

- Possibility to store a swaging program for each rotor model, consisting of various swaging steps with forces and depths selectable by the operator.

- Guaranteed operator ergonomics and safety.

- Full compliance with Industry 4.0 requirements.

Advantages:

Technical features:

- Swaging unit positioned on an independent carriage located on the side of the machine base, sliding on linear guides. Carriage movement along these guides is achieved through a brushless motor.

- Second carriage, installed on the first one, allowing the swaging tool to reach the correct working position based on the diameter of the rotor being processed. The radial movement of this carriage is achieved using a brushless motor.

- Swaging tool consisting of a roller with a diameter and thickness to be defined, interchangeable, and with a surface coating. The tool is mounted at the end of a hydraulic cylinder installed on the radial carriage, allowing for the maintenance of rolling force while compensating for possible surface irregularities of the copper bars.

- Management of the rolling carriage via the operator panel: the operator controls the rotor’s rotation using two buttons on the HMI and positions the rotor in the desired location. Then, he positions the rolling carriage and launches the cycle. The swaging start and end positions along the rotor axis are predefined by the operator by moving the carriage to the positions and saving them as a recipe.

- Possibility to activate the automatic swaging cycle: this entails the machine operating automatically until the completion of the rotor in progress (automatic indexing and swaging of each bar). The operator must create a work program, save it, and can then recall this program whenever needed.

- Integrated remote assistance module: Rimac technicians can remotely connect to the machine and initiate a real-time remote assistance session. By accessing the control panel and PLC and checking the machine’s operation, Rimac’s technician can intervene directly to resolve issues or provide timely guidance. The module can be connected via Ethernet, Wi-Fi, or GSM card.

Via Doberdò 39 – 21046 Malnate (VA) – Italy | Ph: +39 0332 429963 | Fax: +39 0332 424639 | Email: info@rimacmachines.com

© 2023 Rimac Machines – Rimac S.r.l. – VAT nr. IT02569340132