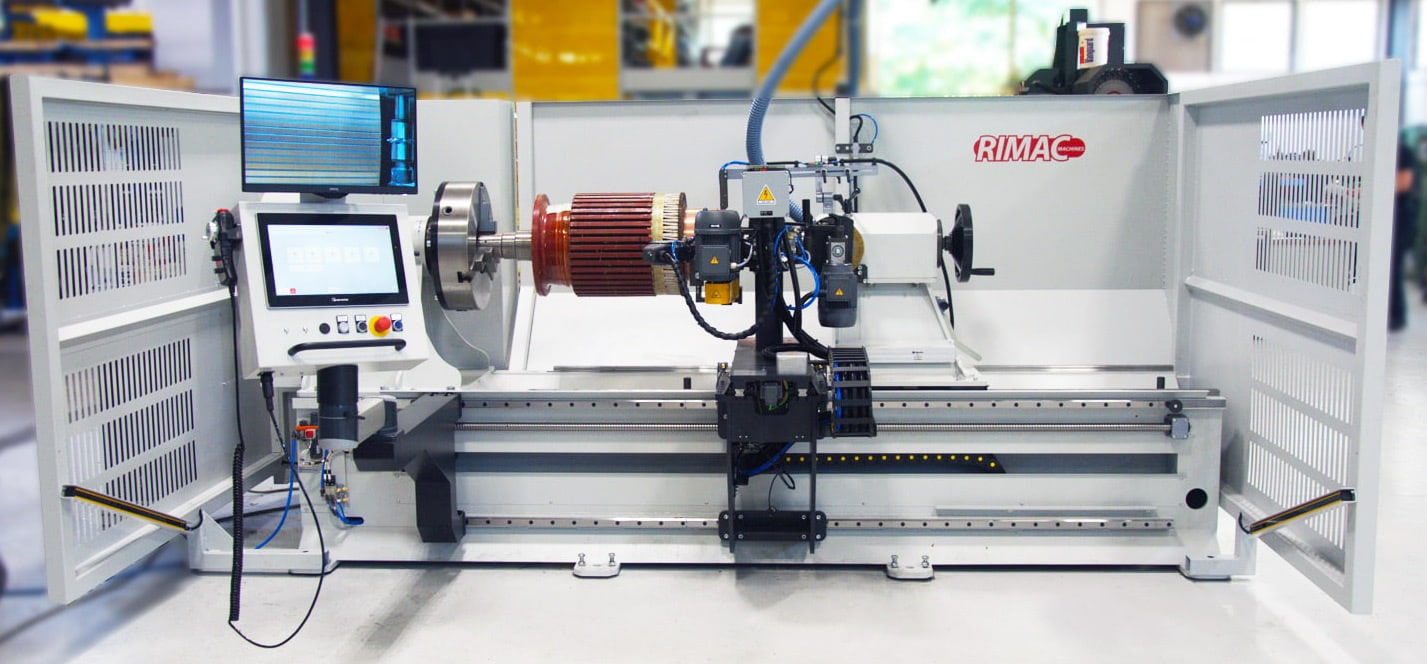

MACHINES AND TOOLS FOR COMMUTATOR UNDERCUTTING

Machines for commutator undercutting, which is the partial removal of insulating material (mica) between the bars of DC motor commutators.

Rimac range of undercutting machines is extensive and includes many different models that can be chosen based on the size of the armature to be treated and the level of automation required.

With over 500 automatic undercutting machines sold in the last 40 years, Rimac is the international market leader for undercutting machines.

- Consistent and high-quality undercutting results over time.

- No manual operation required: a fast, clean, and safe process.

- Possible combination with other functions (brushing, turning, welding, banding, coil leads cut off, and electrical testing).

- Possibility to perform the undercutting process in one single passage initial bar chamfer, final bar chamfer, final bar chamfer at dust groove and also the chamfer along the entire mica.

- Full compliance with 4.0 Industry requirements.

Advantages:

Technical features:

- Micrometric positioning of the cutter thanks to automatic bar search and indexing systems.

- Possibility to choose from 3 different undercutting programs to select the most suitable undercutting mode for the commutator being treated.

- Linear interpolation of the electrical axes, allowing for linear variations in undercutting depth at the beginning and end of the commutator.

- Possibility of mounting a dedicated unit for commutator brushing and for the rounding off of undercut bar edges.

- Possibility to install the undercutting unit in multi-function machines, which combine multiple work functions (brushing, turning, welding, banding, coil leads cut off, and electrical testing).

- Integrated remote assistance module: Rimac technicians can remotely connect to the machine and initiate a real-time remote assistance session. By accessing the control panel and PLC and checking the machine’s operation, the Rimac technician can intervene directly to resolve issues or provide timely guidance. The module can be connected via Ethernet, Wi-Fi, or GSM.

Cutters for undercutting

We can provide various types of undercutting cutters that allow for a wide range of commutator undercut profiles. Rimac cutters are known for their resistance, durability, and high precision.

MODEL N CUTTERS: N-10 Cutter; N-12 Cutter; N-15 Cutter

MODEL V CUTTERS: V-12 Cutter; V-15 Cutter; V-21 Cutter

MODEL T CUTTERS: T-15 Cutter; T-21 Cutter; T-25 Cutter

MODEL C CUTTERS: C-10 Cutter; C-15 Cutter; C-21 Cutter; C-25 Cutter

MODEL CL CUTTERS: CL-8.5 Cutter; CL-13.5 Cutter; CL-19 Cutter; CL-23 Cutter

MODEL CR CUTTERS: CR-8.5 Cutter; CR-13.5 Cutter; CR-19 Cutter; CR-23 Cutter

Upon request, we also supply special cutters with unique technical characteristics that are fully customized based on specific customer needs.

© 2023 Rimac Machines – Rimac S.r.l. – VAT nr. IT02569340132