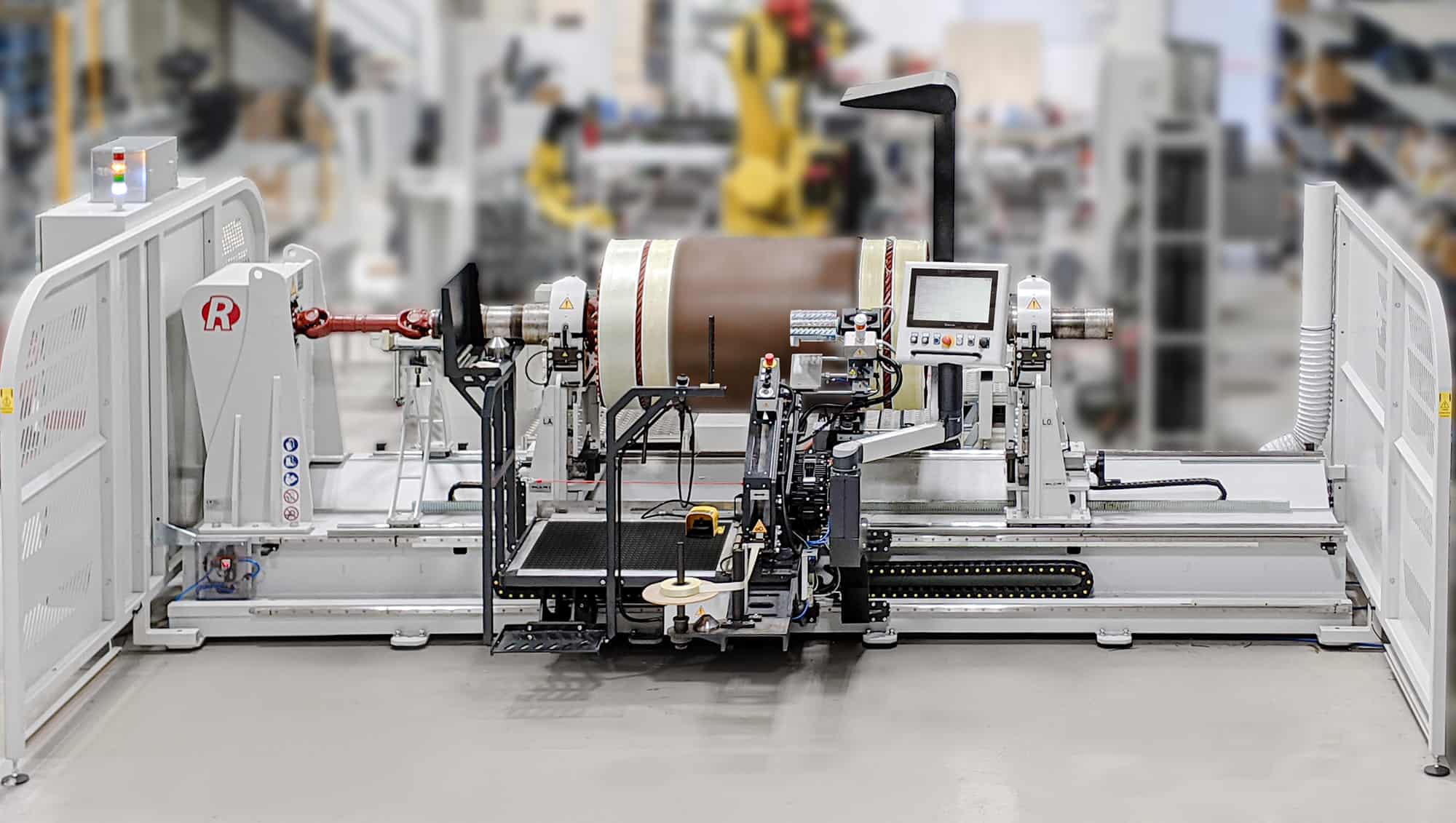

ROTOR BANDING MACHINES FOR WIND GENERATORS

Automatic machines for rotor banding, designed primarily for the controlled and parameterized application of banding tape to wind generator rotors. Rimac offers a wide range of banding machines, including various models to choose from based on rotor size. Rimac banding technology is widely used by wind generator manufacturers worldwide, making Rimac the international market leader for rotor banding machines.

- Optimal and repeatable banding results through automatic tape tension control and precise overlap management.

- Option to integrate pre-heating systems for more effective application.

- Operable in manual, semi-automatic, or automatic mode.

- Comprehensive monitoring of the banding process and results for each rotor zone.

- Possibility to store a work program for each rotor reference, in turn further divided and customizable for each rotor zone.

Advantages:

Technical features:

- Various rotor support and rotation systems to meet specific requirements.

- Load cell for tape tension display and automatic control, with a closed-loop control and regulation system.

- Continuously achievable and maintainable maximum tape tension: 4000 N.

- Electric drives for the translation of the banding carriage and the rotor rotation ensure maximum control over the banding pitch for precise overlap management.

- Tape heating system for preheating the tape to achieve optimal application and better adhesion.

- Dedicated heating system to heat the tape application area to the desired temperature, making the application more effective.

- Compatibility with any kind of pre-preg tape, such as Isoglas, Polyglas, and others.

- Capability to perform the banding cycle in manual, semi-automatic, or automatic mode.

- Operator platform with operator presence sensors, allowing the operator to work near the rotor to apply other materials and monitor the process.

- Possibility to set and store a work program for each specific rotor reference, with the program divided into subprograms for different banding areas. Parameters can be set in a different/ independent way for each defined area.

- The machine provides visual summary graphs of the banding results obtained on each rotor banding zone based on the set banding subprograms. The results are summarized in a report.

- Machine is fully compliant with Industry 4.0 requirements.

- Integrated remote assistance module: Rimac technicians can remotely connect to the machine, initiate real-time remote assistance sessions, and resolve issues or provide timely guidance. The module can be connected via Ethernet, Wi-Fi, or GSM card.

© 2023 Rimac Machines – Rimac S.r.l. – VAT nr. IT02569340132